In the world of agriculture and construction, tractors are deemed as versatile workhorses. However, the extent of their versatility is often hinged on the ease of swapping out various attachments. This is where the skid steer quick attach conversion comes into play, broadening the scope of tasks a tractor can undertake. By transitioning from a pin-on bucket to a quick attach system, tractor operators are able to swiftly switch between different attachments, amplifying the tractor’s functionality manifold.

| Key Aspect | Summary |

|---|---|

| Ease of Attachment Swap | Facilitates hassle-free switch between attachments, saving time and effort. |

| Versatility | Broadens operational scope with ease of interchanging attachments for various tasks. |

| Compatibility Across Brands | Universal design of the quick attach system allows compatibility across various tractor makes and models, unlike proprietary systems. |

| Comparison to Pin-On System | Highlights the limitations of pin-on system like restricted compatibility and manual pinning/unpinning, while presenting the universal compatibility and easy attach/detach feature of Quick Attach Adapter. |

| Installation Guide | Provides a detailed step-by-step guide on transitioning to a front end loader quick attach system, emphasizing preparation, alignment, securing, and maintenance. |

| Retrofitting Existing Bucket | Guides on retrofitting an existing pin-on bucket for quick attach compatibility, including steps like acquiring/fabricating a quick attach plate, welding it to the bucket, and maintaining the retrofit. |

| Conclusion | Advocates for the adoption of quick attach system for operational flexibility, outlining the straightforward transition process and substantial benefits. |

| FAQs | Addresses common questions regarding the functionality, compatibility, conversion process, installation, and maintenance of quick attach systems. |

What is a Skid Steer Quick Attach?

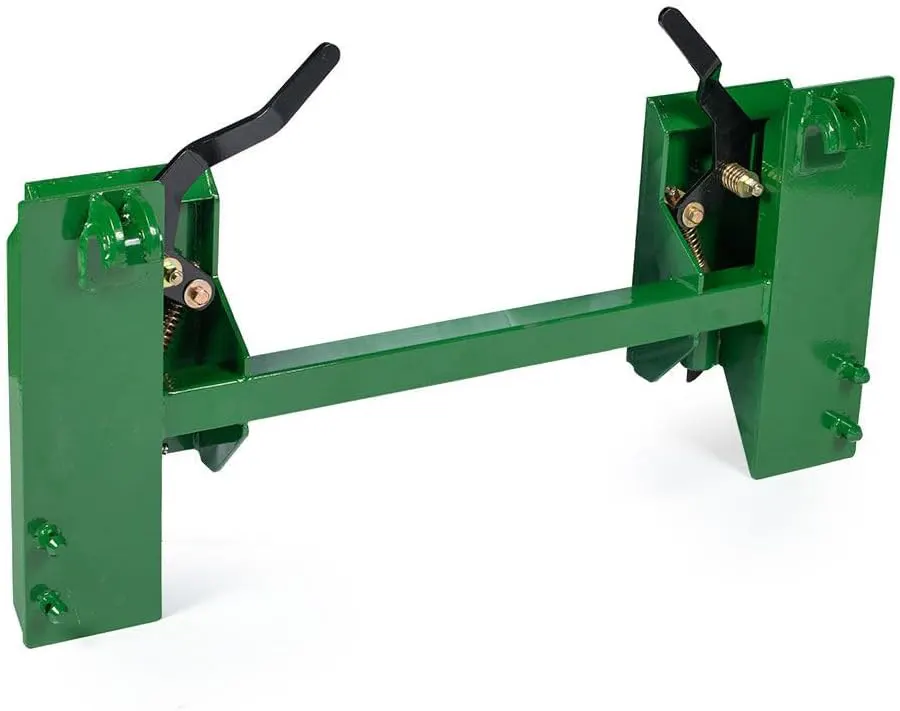

A skid steer quick attach adapter is a piece of equipment that attaches to the front end loader of a tractor to allow for easy and quick attachment of various skid steer attachments such as buckets, forks, and grapples. The quick attach system is designed to save time and effort by allowing you to quickly switch between different attachments without the need for manual connection.

Why Consider a Skid Steer Quick Attach Conversion?

Ease of Attachment Swap

The essence of a quick tach system lies in the ease it imparts when swapping out attachments. Whether it’s a bucket, pallet forks, or a grapple, the quick connect conversion for tractor front end loader ensures a hassle-free switch, saving both time and effort. This was well-illustrated by Marvin’s experience shared on his feature with Ask Tractor Mike, where he converted his Kubota’s pin on bucket to a quick attach system. The process involved removing the pins, detaching the bucket, and then mounting the quick attach plate onto the tractor’s front end loader. The ease of this transition underscored the practicality of adopting a quick attach system.

Versatility

The ability to easily interchange attachments significantly broadens the operational scope of a tractor. From material handling and loading to more specialized tasks such as grappling or stump removal, the possibilities become extensive. This was exemplified in a video shared on the channel where the tractor owner demonstrated how a quick attach system facilitated an effortless switch between a bucket and pallet forks, thereby augmenting the tractor’s utility.

Compatibility Across Brands

Unlike some proprietary systems like that of John Deere, the skid steer quick attach system boasts a universal design, making it compatible across various tractor makes and models. This feature is essential for those who may have different tractor brands but desire a standardized quick attach system for simplified operations.

| Aspect | Traditional Pin-On System | Quick Attach Adapter |

|---|---|---|

| Compatibility | Limited to specific models or brands | Universal design compatible with various implements |

| Operational Efficiency | Manual pinning/unpinning required | Easy attach/detach without tools |

| Versatility | Restricts users to a narrow range of implements | Expands range of implement options |

| Interoperability | Lesser due to brand/model restrictions | Greater as it adheres to industry standards |

| Implement Options | Limited | Wide array including buckets, pallet forks, bale spears, etc. |

| Industry Adoption | Declining due to limitations | Widely adopted due to universal compatibility |

Limitations of the Traditional Pin-On System

The Quick Attach adapter addresses several issues inherent to the traditional pin-on system, particularly revolving around compatibility with various implements. In a farming or construction setting, the ability to switch between different implements swiftly is crucial for operational efficiency. The pin-on system tends to be restrictive as it usually requires manual pinning and unpinning to change implements, and often, the compatibility is limited to specific models or brands. This system’s design tends to confine users to a narrow range of implements, which can hinder the versatility and overall productivity of the tractor.

Universal Compatibility with the Quick Attach Adapter

On the other hand, the Quick Attach adapter is designed to universalize the connection between the front-end loader and various implements. Its design adheres to a standardized mechanism, making it compatible with a broader range of implements regardless of their make. This universal compatibility is a game-changer as it opens up a vast array of implement options for tractor owners. They can now easily attach or detach various implements like buckets, pallet forks, bale spears, grapples, and more, from different manufacturers, without the need for any tools or the cumbersome process of manual pinning and unpinning.

3rd Party Aftermarket Adapters available on Amazon:

John Deere Quick Attach Adapter | Kubota Quick Attach Adapter | Universal Quick Attach Adapter

Front End Loader Quick Attach Installation Guide

Transitioning to a front end loader quick attach system can significantly enhance the versatility of your tractor. The process involves several steps which, when followed meticulously, ensure a smooth installation and secure operation. Below is a detailed step-by-step guide based on the shared experiences from users:

Step 1: Preparation

- Equipment Check: Ensure you have all the necessary equipment including the quick attach plate, pins, bolts, and tools such as wrenches and possibly a torque wrench for precise tightening.

- Safety Precautions: Ensure the work area is clear, and the tractor is on a stable, level surface. It’s advisable to have an assistant to help with lifting and aligning the quick attach plate.

Step 2: Removal of Existing Pin-On Bucket

- Unpinning: Remove any pins, bolts, or other hardware securing the pin-on bucket to the front end loader.

- Detachment: Carefully detach the bucket from the front end loader and set it aside in a safe area.

Step 3: Cleaning and Inspection

- Cleaning: Clean the mounting area on the front end loader to remove any dirt, grease, or debris.

- Inspection: Inspect the mounting area for any damages, wear, or misalignments that might affect the installation of the quick attach plate.

Step 4: Aligning the Quick Attach Plate

- Positioning: Position the quick attach plate onto the front end loader, ensuring it is level and correctly aligned with the mounting holes.

- Assistance: It’s beneficial to have an assistant help hold the quick attach plate in place while aligning the holes.

Step 5: Securing the Quick Attach Plate

- Inserting Pins: Insert the provided pins through the aligned holes, securing the quick attach plate to the front end loader.

- Bolting: Insert and tighten the bolts securely using the appropriate tools. A torque wrench can be used to ensure the bolts are tightened to the manufacturer’s specifications.

Step 6: Final Inspection and Testing

- Inspection: Conduct a thorough inspection to ensure the quick attach plate is securely attached and there are no loose bolts or pins.

- Operational Test: Attach an accessory such as a bucket or pallet forks to the quick attach plate and conduct a test to ensure the quick attach system operates smoothly and securely.

Step 7: Maintenance

- Regular Checks: Periodically inspect the quick attach system for any wear, damages, or loose bolts and pins.

- Greasing: Keep the attachment points well-greased to ensure smooth operation and to prolong the lifespan of the quick attach system.

Following this detailed installation guide will help ensure a successful transition to a front end loader quick attach system, thereby expanding the range of tasks your tractor can efficiently undertake.

Through this structured process, converting to a skid steer quick attach system becomes a manageable task, promising a world of operational versatility to tractor owners regardless of the tractor brand they possess.

Need a little more guidance? Check out Mountain Mike on YouTube for comprehensive installation overview

Retrofitting Your Existing Bucket for Quick Attach Compatibility

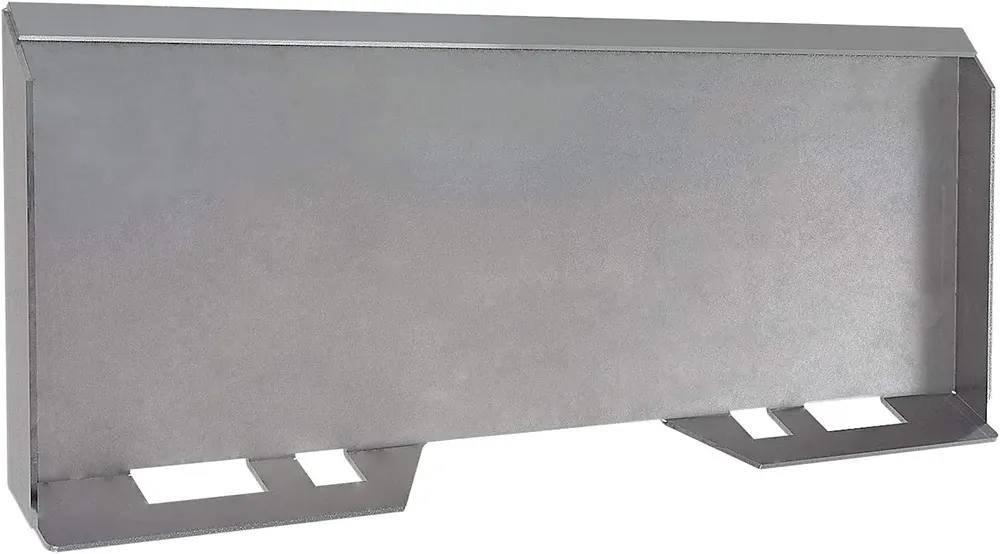

3rd Party Skid Steer Quick Attach Mounting Plate available on Amazon:

Universal Quick Attach Mounting Plate

Transitioning to a quick attach system doesn’t necessitate the abandonment of your existing pin-on bucket. With a bit of modification, you can retrofit your bucket to be compatible with your newly installed quick attach system. Here’s a systematic approach based on the experiences shared by users:

Step 1: Assess and Prepare the Bucket

- Inspection: Examine your bucket for any damages or excessive wear that may need repair before proceeding.

- Measurement: Measure the dimensions of the front end loader quick attach plate and the mounting area on the bucket to ensure a proper fit.

Step 2: Remove the Pin-on Mounting Hardware

- Unpinning: Remove any pins, bolts, or other hardware used in the pin-on connection system from the bucket.

- Cleaning: Clean the areas around the mounting points to ensure a smooth retrofitting process.

Step 3: Acquire or Fabricate a Quick Attach Plate

- Purchase: Obtain a quick attach plate that is compatible with both your tractor’s front end loader and the dimensions of your bucket.

- Custom Fabrication: If a standard quick attach plate doesn’t fit, consider having one custom fabricated to match your bucket’s specifications.

Step 4: Align and Weld the Quick Attach Plate

- Alignment: Align the quick attach plate onto the bucket ensuring it is level and in the correct position for secure attachment to the front end loader.

- Welding: Have a professional welder securely weld the quick attach plate to the bucket. Ensuring the welding is done accurately is crucial for the safety and functionality of the retrofitted bucket.

Step 5: Inspect and Paint

- Inspection: Post welding, inspect the attachment points to ensure a secure and proper fit.

- Painting: Consider painting the welded areas to match the bucket, which not only enhances the appearance but also provides a layer of protection against rust.

Step 6: Attach and Test

- Attachment: Attach the retrofitted bucket to the front end loader using the quick attach system.

- Operational Test: Conduct a thorough operational test to ensure the retrofitted bucket securely attaches, detaches, and operates as intended.

Step 7: Maintenance

- Regular Checks: Periodically inspect the welding points and the quick attach mechanism for any wear or damages.

- Greasing: Keep the attachment points well-greased to ensure smooth operation and to prolong the lifespan of the quick attach system.

By following this systematic approach, you can effectively retrofit your existing pin-on bucket to be compatible with a skid steer quick attach conversion, thereby extending the versatility of your tractor without the need to invest in a new bucket.

Need a little more guidance? Check out Ask Tractor Mike on YouTube for comprehensive installation overview

Conclusion

Embracing a skid steer quick attach conversion is a prudent move for any tractor owner aiming for operational flexibility. The transition process, as outlined, is straightforward, and the benefits, as evidenced by the shared experiences, are substantial. By doing so, tractor operators can now effortlessly switch between a myriad of attachments, transcending the traditional limitations posed by a pin-on bucket system.

Frequently Asked Questions (FAQs) on Front End Loader Quick Attach System

What is a front end loader quick attach system?

A front end loader quick attach system is an interface for tractor loaders that allows for easy and fast attachment and detachment of various accessories like buckets, pallet forks, bale spears, etc., without the need for tools. It replaces the traditional pin-on system, making it quicker and more convenient to switch between different attachments.

Is a quick attach system universal for all tractor models?

While quick attach systems aim for universal compatibility, not all are suited for every tractor model. It’s essential to check the specifications and compatibility of the quick attach system with your particular tractor model before purchasing.

How do I convert my pin-on bucket to a quick attach bucket?

To convert a pin-on bucket to a quick attach bucket, you’ll need to weld a quick attach plate to the existing pin-on bucket. It’s advisable to have this done by a professional welder to ensure accuracy and safety. The alignment and welding should be precise to ensure the bucket attaches securely to the quick attach system on your front end loader.

Can I install a quick attach system myself, or do I need professional assistance?

It’s possible to install a quick attach system yourself if you have the necessary tools and follow the manufacturer’s instructions meticulously. However, if you are unsure or uncomfortable with the process, it’s advisable to seek professional assistance to ensure a safe and correct installation.

What maintenance is required for a quick attach system?

Regular inspection and maintenance are crucial for a quick attach system. This includes checking for any wear, damages, or loose bolts and pins, ensuring that the attachment points are well-greased for smooth operation, and keeping the system clean from dirt and debris. Following the manufacturer’s maintenance guidelines will help prolong the lifespan and ensure the safe operation of the quick attach system.

Disclaimer: The information provided in this blog post is for informational purposes only. Victory Tractor Implements and its affiliates, authors, and contributors are not responsible for any damages, injuries, or losses that may result from the application of the information provided. It is the reader’s responsibility to ensure that any modifications or installations are done correctly and safely. Always consult with a professional or expert before making any changes to your tractor or equipment.

Victory Tractor Implements is proud to offer a wide range of products including flail mowers, wood chippers, rotary tillers, and backhoes, all designed to be connected directly to your tractor’s PTO for maximum efficiency and performance. In addition, we also offer winter equipment such as snow plows and snow blowers, designed for use with skid steers.

We source all of our equipment directly from the manufacturer and pass the savings on to our customers. As always, the team is standing by to answer any questions to assist with your decision. Victory support can be reached directly at (562) 534-8182 or sales@etractorimplements.com